Top Quality Lift Maintenance Repair by Qualified Professionals

Wiki Article

Unlocking the Secrets to Reliable Lift Services: Specialist Insights Disclosed

In the world of lift fixing and upkeep, discovering the methods that cause effective and efficient solution is comparable to decoding a complex challenge. Specialist understandings serve as the directing light with the labyrinth of challenges encountered by upkeep experts in the vertical transport market. By delving right into the midsts of proactive strategies, repairing methods, and the constant pursuit of ability enhancement, the course to boosting maintenance criteria exposes itself. As we start this journey to debunk the secrets behind structured lift fixings, a world of opportunities arises, promising a future where downtime is decreased, security is prioritized, and functional excellence comes to be the norm.Common Lift Repair Service Obstacles

Another widespread obstacle in lift fixings is the absence of appropriate maintenance records. Without accurate upkeep documents, repair service service technicians might battle to detect problems efficiently or anticipate potential troubles. This can lead to longer repair work times and enhanced costs as professionals function to fix problems without historical information to assist them.

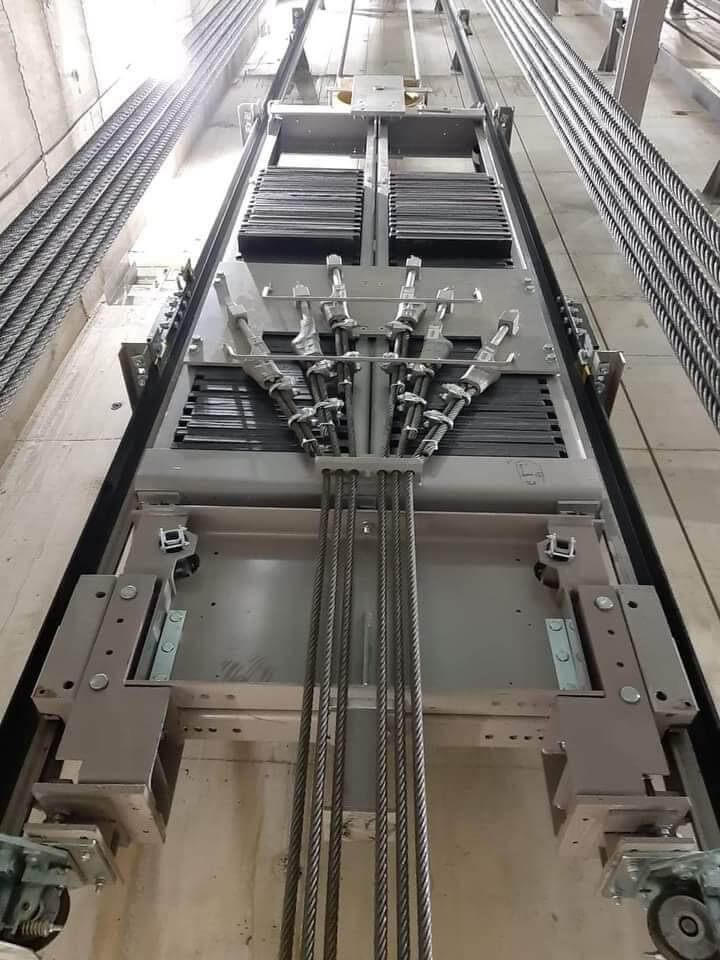

Additionally, availability issues within lift shafts can position substantial obstacles during repairs. Minimal room, awkward angles, and complicated equipment can make it challenging for service technicians to get to the required elements for repair, prolonging the total repair work process - Lift Maintenance Repair. By resolving these typical challenges proactively, lift repair service professionals can boost operational performance and ensure the smooth performance of vertical transport systems

Proactive Maintenance Methods

Implementing positive upkeep techniques is extremely important for guaranteeing the long life and optimal efficiency of lift systems. By taking on a positive strategy to maintenance, building supervisors and lift maintenance teams can attend to potential issues prior to they rise into expensive fixings or downtime. One effective method is to develop a normal maintenance routine that consists of comprehensive examinations, lubrication of relocating parts, and testing of security features.

In addition, buying training programs for upkeep team can boost their abilities in recognizing possible concerns and executing preventative upkeep jobs properly - Lift Maintenance Repair. By encouraging upkeep groups with the understanding and devices required to proactively preserve lift systems, structure owners can minimize disruptions, extend the lifespan of their lifts, and make certain a secure and reliable upright transport experience for passengers

Fixing Techniques

Efficient repairing techniques are important for without delay determining and settling issues with lift systems to lessen downtime and Resources make sure ideal efficiency. One efficient strategy is to begin with a detailed visual assessment of the lift components, checking for any kind of noticeable indications of misalignment, wear, or damage.

Enhancing Repair Abilities

Enhancing effectiveness in lift system repair services is an essential aspect of guaranteeing optimal capability and reducing operational disturbances. Elevator technicians must consistently work on honing their fixing skills to meet the needs of modern lift systems. One vital method for enhancing fixing skills is normal training sessions that focus on both academic understanding and practical application. These sessions can cover a variety of topics such as brand-new technologies in the market, troubleshooting complicated concerns, and security methods. Furthermore, professionals can take advantage of hands-on experience under the advice of seasoned specialists to improve their analytic capacities and decision-making skills in real-time repair work scenarios.Furthermore, staying updated with the most recent advancements in lift innovation is vital for technicians looking to improve their repair service abilities. This entails proactively inquiring concerning new parts, software updates, and maintenance methods to successfully identify and remedy problems. By spending effort and time right into constant discovering and functional experience, lift service technicians can considerably boost their repair work competencies and add to the efficient functioning of lift systems.

Elevating Upkeep Requirements

Elevating upkeep criteria in lift systems is extremely important for making certain long term operational effectiveness and safety. Regular upkeep not just improves the performance of lift systems yet additionally lessens the danger of unexpected breakdowns and makes certain the security of individuals. By adhering to rigorous maintenance protocols, lift proprietors and operators can considerably reduce the chance of expensive repair work and downtime.Implementing a thorough maintenance schedule that consists of regular examinations, lubrication of relocating parts, and aggressive replacement of used elements is essential. Making use of look these up sophisticated technologies like IoT sensing units and predictive upkeep software application can aid in checking the lift's condition in real-time, making it possible for timely treatments before concerns intensify. In addition, offering continuous training for upkeep personnel on the most up to date market criteria and finest practices is necessary for upholding upkeep quality.

In addition, fostering a culture of responsibility and focus to information among maintenance groups can further boost maintenance standards. Motivating open communication networks for reporting and addressing maintenance worries promptly can help in maintaining a high level of lift system dependability. Eventually, by boosting and focusing on upkeep criteria, lift systems can run successfully and securely for a prolonged duration.

Verdict

To conclude, reliable lift fixings call for aggressive upkeep approaches, repairing strategies, and boosted fixing abilities. By raising and attending to typical challenges maintenance standards, upkeep specialists can successfully make sure the smooth operation of lifts - Lift Maintenance Repair. Executing these expert understandings can cause enhanced efficiency, lowered downtime, and boosted security for both passengers and toolsIn the world of lift repair service and maintenance, revealing the techniques that lead to effective and effective service is comparable to deciphering an intricate challenge.Another widespread difficulty in lift repairs is the absence of appropriate upkeep records. By adopting an aggressive method to upkeep, building supervisors and lift maintenance groups can attend to potential concerns before they rise into pricey repair services or downtime.In conclusion, reliable lift repair work call for positive maintenance approaches, troubleshooting strategies, and enhanced fixing skills. By resolving common obstacles and elevating maintenance criteria, maintenance experts can properly make sure the smooth procedure of lifts.

Report this wiki page